Multi-Touch Technology Overview

The term “multi-touch” is now in common use to describe any touch screen that can recognize more than one point of contact; in effect the use of two or more fingers simultaneously. Multi-touch is considered by many to become a widely-used interface mainly because of the speed, efficiency and intuitiveness of the technology. However, there are now several different types of multi-touch, technology. Below is an explanation of the different types of multitouch technology available which also acts as a guide for the terms we use for describing the touch screens we supply.

IR or Infrared Touch

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any input including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and point of sale systems which can not rely on a conductor (such as a bare finger) to activate the touchscreen.

An infrared touchscreen uses an array of X-Y infrared LED and photodetector pairs around the edges of the screen to detect a disruption in the pattern of LED beams. These LED beams cross each other in vertical and horizontal patterns. This helps the sensors pick up the exact location of the touch. A major benefit of such a system is that it can detect essentially any input including a finger, gloved finger, stylus or pen. It is generally used in outdoor applications and point of sale systems which can not rely on a conductor (such as a bare finger) to activate the touchscreen.

- Vertical and Horizontal Infrared Beams

- A finger touches the screen and disrupts the beams

- The x, y location of the contact is calculated by the controller and transmitted to the PC.

Unlike capacitive touchscreens, infrared touchscreens do not require any patterning on the glass which increases durability and optical clarity of the overall system.

Capacitive Touch

Capacitive touchscreens are highly accurate and respond instantly when lightly touched by a human finger. A capacitive screen is usually made of one insulating layer, such as glass, which is coated by a transparent conductive material on the inside. Since the human body is conductive, which means electricity can pass through it, the capacitive screen can use this conductivity as input. When you touch a capacitive touchscreen with your finger, you cause a change in the screen’s electrical field. This change is registered, and the location of the touch is determined by a processor. capacitive touchscreens rely on the electrical change caused by a light touch of a finger. This is the reason you cannot use a capacitive screen while wearing gloves – the gloves are not conductive, and the touch does not cause any change in the electrostatic field.

Capacitive touchscreens are highly accurate and respond instantly when lightly touched by a human finger. A capacitive screen is usually made of one insulating layer, such as glass, which is coated by a transparent conductive material on the inside. Since the human body is conductive, which means electricity can pass through it, the capacitive screen can use this conductivity as input. When you touch a capacitive touchscreen with your finger, you cause a change in the screen’s electrical field. This change is registered, and the location of the touch is determined by a processor. capacitive touchscreens rely on the electrical change caused by a light touch of a finger. This is the reason you cannot use a capacitive screen while wearing gloves – the gloves are not conductive, and the touch does not cause any change in the electrostatic field.

- Small amount of voltage is applied to the four corners of the touch screen

- A finger touches the screen and draws a small amount of current to the point of contact, causing a voltage drop.

- The x, y location of the contact is calculated by the controller and transmitted to the PC.

Since capacitive screens are made of one main layer, which is constantly getting thinner as technology advances, these screens are not only more sensitive and accurate, the display itself can be much sharper, as seen on devices such as the iPhone. PCAP may be used for screens under 42″, however, it’s significantly much more expensive when compared to other touchscreen technology.

Resistive (Nano) Touch

The resistive touchscreen is the most common type of touchscreen. The resistive touchscreen relies on resistance – the pressure you apply causes the screen to respond. A resistive touchscreen is made out of two thin layers separated by a thin gap. These two layers both have a coating on one side, with the coated sides facing each other inside the gap. When these two layers of coating touch each other, a voltage is passed, which is in turn processed as a touch in that location.

The resistive touchscreen is the most common type of touchscreen. The resistive touchscreen relies on resistance – the pressure you apply causes the screen to respond. A resistive touchscreen is made out of two thin layers separated by a thin gap. These two layers both have a coating on one side, with the coated sides facing each other inside the gap. When these two layers of coating touch each other, a voltage is passed, which is in turn processed as a touch in that location.

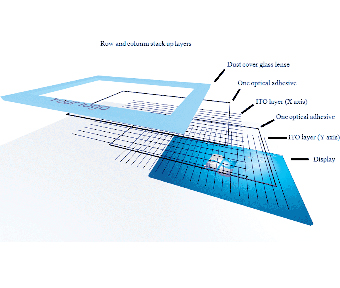

- Top layer is made from a film, top circuit layer, and ITO conductive coating. Bottom layer consists of a spacer dot, ITO conductive coating, bottom circuit layer, and glass or acrylic backing panel.

- Touch creates contact on resistive circuit layers, closing a switch.

- Controller determines between layers to get coordinates.

Resistive screens have been improving greatly over the years, and today many lower-end smartphones boast a resistive screen which is no less accurate than high-end devices.

PCAP or Projected Capacitive Touch

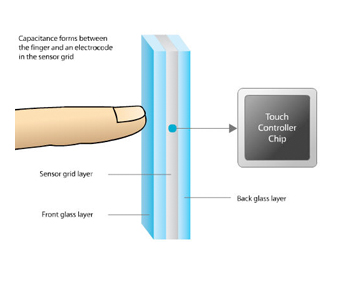

Projected Capacitive Touch (PCT or PCAP) technology is a variant of capacitive touch technology. All PCT touch screens are made up of a matrix of rows and columns of conductive material, layered on sheets of glass. This can be done either by etching a single conductive layer to form a grid pattern of electrodes, or by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid. Voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the “tracks”, the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid (intersection). Therefore, this system is able to accurately track touches.

Projected Capacitive Touch (PCT or PCAP) technology is a variant of capacitive touch technology. All PCT touch screens are made up of a matrix of rows and columns of conductive material, layered on sheets of glass. This can be done either by etching a single conductive layer to form a grid pattern of electrodes, or by etching two separate, perpendicular layers of conductive material with parallel lines or tracks to form a grid. Voltage applied to this grid creates a uniform electrostatic field, which can be measured. When a conductive object, such as a finger, comes into contact with a PCT panel, it distorts the local electrostatic field at that point. This is measurable as a change in capacitance. If a finger bridges the gap between two of the “tracks”, the charge field is further interrupted and detected by the controller. The capacitance can be changed and measured at every individual point on the grid (intersection). Therefore, this system is able to accurately track touches.

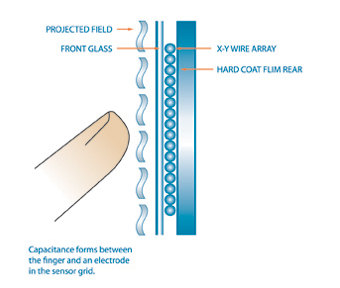

- PCAP uses a projected field on a glass layer. Under the glass layer is an x,y wire arroy on a hard coated film rear.

- Capacitance forms between the finger and an electrode in the sensor grid.

Unlike traditional capacitive touch technology, it is possible for a PCT system to sense a passive stylus or gloved fingers. However, moisture on the surface of the panel, high humidity, or collected dust can interfere with the performance of a PCT system. There are two types of PCT: mutual capacitance and self-capacitance.